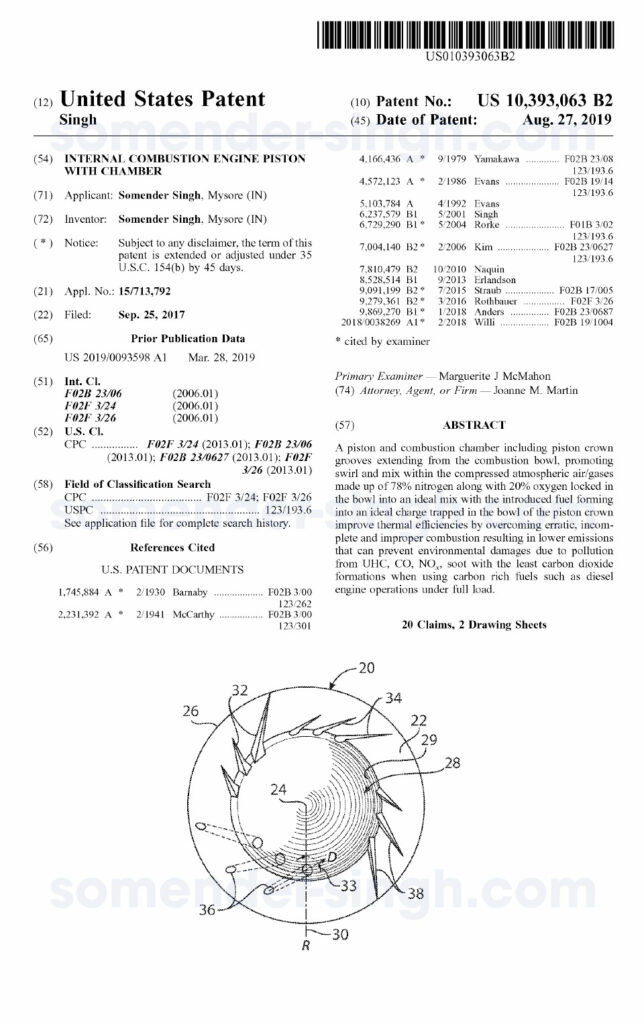

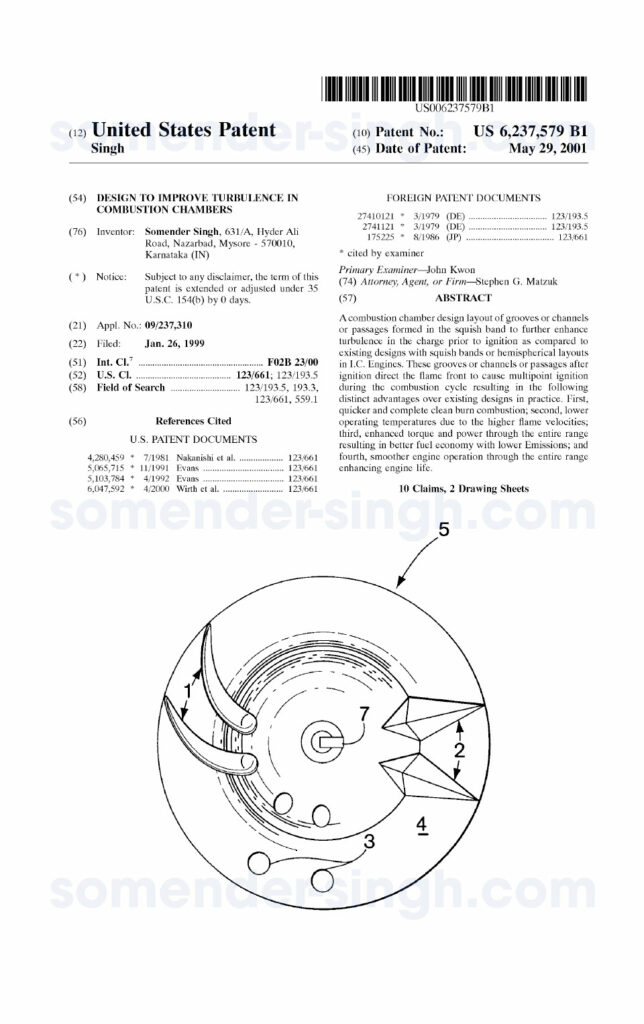

Introduction to my Combustion Chamber Innovations and Theory, based on my US Patents : US6237579 & US10393063 achieved after extensive Cut & Try experiments to refine and perfect my designs on Road & Tracks.

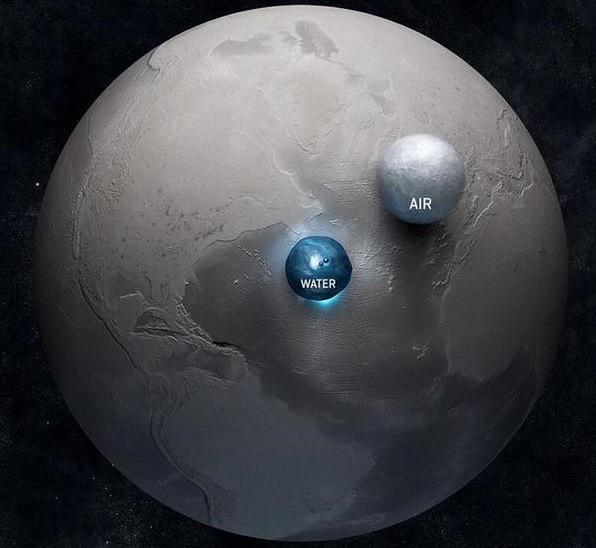

Some Basic Facts of Combustion: Without Oxygen there is no form of Combustion. Any form of Combustion results in Oxides, Finally, Nitrogen is the largest commodity making up the charge and its expansions define the outcome in Torque & Power out of In-Cylinder Combustion !

This Unique Design is based on Fluid Dynamics and its directives to induce Directional Turbulence to achieve a better mix in the trapped Air & Fuel charge, Before, During and After Combustion with the least interference of “Ping or Knock” is the USP of my design ! This Unique design promotes Laminar Combustion out of a better Mix & Blend with the trapped N2/Nitrogen which happens to be the largest commodity (78%) in the air and in the charge, with (20%) O2/Oxygen along with metered tiny droplets of fuel forming into a volatile charge under compression, trapped inside the cylinder before Ignition occurs.

This simple easy to implement design modifications to the Squish Areas of Combustion Chambers requires no redesigning or large investments to carry out these changes, to promote better fuel burning inside cylinders to achieve lot more Torque & Power with lower raw emissions out of exhaust ports. This technology has been conceived, perfected and Made in India further Patented in the USA out of self funding with over 5 Decades of R&D to refine my designs to the present state.

My specific design changes to the face of combustion chambers promotes a dynamic state of mix in the air & fuel mixtures, resulting in quicker combustion due to a shorter Ignition Delay period which results in lesser heat absorptions into the cylinder walls due to Accelerated Laminar Clean Burn Combustion along with many other advantages relating to lesser Smoke, Soot, Noise and Cooler running with better Kmpl / Mpg too. This would be the dream of every Designer and Manufacturers to achieve the above spending Millions as top Priorities.

These simple modifications to Combustion Chambers goes past present thresholds of Combustion without changing the geometry of an engine or its components or needing any redesigning of the internals of engines or its complex onboard systems governing the engine management systems to achieve the above gains after simple cost effective modifications – Which never Existed in any Text or Designs of Combustion Chambers in the Last Century or this Century to bring out the Hidden Potentials of Fuel Burning in IC Engines.

These Claims alone will be Challenged by All !? As It is Impossible to achieve all the above advantages out of Simple Modifications to existing Combustion Chambers of CI & SI Engines in this Day and Age of Perfections ! To most Accelerated Combustion will only result in excessive heat resulting in more NOx which is a forbidden commodity in today’s strict norms.

Kindly study my Patents in detail to understand my – Out of The Box Thinking to achieve the much needed Air & Fuel Mixing in the right proportions under higher compression ratios achieving Controlled Combustion. My design relates to what happens 1/2 Inch on either side of TDC (piston movements) Before Ignition followed by Ignition Delay followed by unpredictable combustion taking over once ignited. As this is the most crucial period in any IC Engine to achieve optimum Thermal Efficiencies form the fuel in use, under max load and conditions without going past red lines that destroy engines in short periods.

The only known methods to control combustion temperatures inside cylinders from the Outside’s is by EGR, which have their own issues and disadvantages related to malfunctions and emissions of UHC & CO. Yet it is the only known source to control and reduce NOx during uncontrolled combustion inside cylinders – Which my design can reduce and overcome the NOx issues with the help of Laminar Combustion.

The Quest for Power has led to very high Combustion Pressures & Temperatures further by downsizing New-Gen Turbocharged engines to achieve a smaller Carbon Foot Print has resulted in lifeless Air, which is very harmful for breathing, as all Life-giving Microbes in the air are dead due to the exposure of very high temperatures, further filled with Carcinogenic fumes resulting in serious health issues in Urban areas having little Vegetation and lacking tree shade due to road widening and concrete ,,,,,

If given an opportunity – I can Display & Demonstrate my simple innovations followed by road tests to see the actual results before heading to the Dyno & Emission Labs to find out more of “How & Why“ ?! For a better understanding of this “never seen before, unique designs,” applicable to Combustion Chambers of both SI & CI Engines to take this design forward in the interests of all, considering the challenges faced by the Industry and our Environment due to excessive Emissions & Greenhouse Gases leading to Climate Changes for the worse ! As Very few workable solutions exist, except for Catalytic Convertors and AdBlue and other Additives all adding to the cost of transportation. In Reality: Stringent CAFE standards have pushed the Bar of Efficiency through the Sky demanding 113 Grams of CO2 Per Km by April 2022. This Chemical Equation relating to combustion and the outcome of CO2 is fixed – One Litre of Diesel Combusted, exits 2.5+ Kgs CO2 into our Atmosphere which the whole world is trying its Best to Reduce and Improve upon. By Improving the Thermal Efficiency, we can only extend the Distance and Loads. But the ratio of 2,5+ Kgs Of CO2 per Liter remains constant. My Goals are to achieve a Smaller Carbon Footprint Per Km / Ton with my simple easy to implement Innovations out of better BMEP to bring out the hidden potentials of Combustion.

Present trends to achieve BS6 norms are by Super High Pressure Fuel Systems, laced with electronics backed by expensive Catalytic Converters boxed with NOx Buster, using AdBlue to dissolve Emissions & NOx to sell their products. We have also seen the short cuts, people at VW Group and others have taken to mask emissions and eventually caught cheating and fined in excess to $20+Billion as penalty with Millions of malfunctioning Automobiles Junked. This shows the Limitations faced by the industry and designers to overcome the Present Challenges to meet the norms with consistency, as there are no further Euro or BS 7 & 8 Norms in the future ?!?

As Per Global Norms: The Cut Off dates to phase out the manufacture of all types of IC Engines across the World due to Greenhouse Gases and Emissions are set for 2035 AD ! As the Industry has few solutions or options to overcome and improve on present thresholds & limitations of combustion economically, to overcome the challenges set by World Bodies. This leaves us with only 12 more years to refine and showcase whatever “ We Claim as Breakthroughs “ before the curtain finally comes down on IC Engines forever !?

Engineers have carried out CAD CAM Simulation on my designs and found No difference, In fact lower cold compression etc,. !? The software used by the Industry and Labs are supplied by Ricardo or AVL or so many others, are a copy from each other, just predicting what could be happening based on Data and Geometry. When “Grooves, Channels and Passages “never existed, all this while ? How could they write out Software Programs concerning abstract Fluid Dynamics which are random and complex in nature with no fixed rules. Like the Weatherman’s predictions of Rains, and it turns out – Sunny All Day ! Nobody has “ One Stop Solutions ” for all the Challenges faced in today’s blends of Ethanol / CNG and, Hydrogen as suggested by Hon’ble Ministers & Governments as solutions !

My proposals over the years to Manufacturers, Govt’s and others have been side lined and suppressed due to lack of understanding of new Concepts & Ideas based on their understandings and trends set by the Industry as upper Limits.

It has taken me Decades to achieve this State of Perfection, after spending lots of Time & Money to Transform 100’s of SI & CI – MPFI & CRDI Engines of different Makes & Models and more recently, Gasified Engines running on LPG & CNG to achieve better results with minor modifications.

Kindly see the possibilities of this Unique “ Made and Invented In India “ Concept that took shape on Road & Track followed by Race & Rally experiments out of fine tuning a variety of engines, before applying for 2 US Patents in the crucial area of Combustion Chambers, further establishing the principles of Laminar Combustion – Cycle after Cycle which is not possible by the book of IC Engines. My journey is based on Self learning out of Self-funding to achieve all these Innovations single handed, spanning over 5 Decades to further perfect this Unique – Turbulence Inducing Design beyond Doubts. What I am Projecting is, Laminar Combustion over unpredictable Turbulent Combustion as seen in most engines due to lack of proper Air & Fuel Mixing going past flash points of fuels due to the heat generated out of higher compression ratios and the use of EGR to control these fluctuations.

Be it, Liquids or Gaseous Fuels, this form of Directional Turbulence achieves rapid charge motion nearing TDC and is capable of dissolving the Un-burnt HC & CO inside the cylinder into expansions more efficiently during the combustion cycle resulting in lesser raw emissions out of the exhaust ports with a bonus of more Torque & Power – Out of simple modification to existing combustion chambers of Both SI & CI Engines to bring out the hidden potentials of Fuel Burning like never before.

We are all Air Breathing Engines, Without Oxygen there is no Combustion Taking Place. When Air Oxidizes with the Fuel, the resultants are “Die Oxides “ and the heat generated expands the Largest trapped element called Nitrogen into expansions to push the Piston down the cylinder to spin the crank shaft. This is measured by BMEP: Brake Mean Effective Pressures which happens to be the Yardstick for all IC Engine Performances ! Hence the even spread of N2 with all the other ingredients during combustion is very essential to brings out the rapid expansions in the N2 to achieve maximum BMEP during the power stroke in the absence of Ping or Knock. This leads us to achieve “More Out of Less” Out of the Least Changes and Inputs in present IC Engines – This is the USP of my Turbulent Designs relating to charge motion out of fluid dynamics to maintain Charge Homogeneity through the entire process of combustion. Looking forward to your Comments and your Views to see the Possibilities of this Simple – Invented in India Innovations relating to Combustion which never existed, with Improvements in Fuel Efficiencies as Top Priority in today’s demanding requirements in over A Billion Polluting Engines needing Band Aids to bring down Green House Gases ! “ This happens to be the Need of the Hour ” as they are the Leading Causes of Global Warming with unheard temperatures & cold waves, manifesting into Climate Changes, which we have never seen or experienced before !

Coming to Ethanol, Methanol, Bio-Fuels and Hydrogen and other Gases – All need Heat & Electricity to produce – Even to form Ice we need Heat Exchangers. Storage & Transportation of these volatile gases under very high pressures is very critical and can easily turn into Lethal Bombs ! The Calorific values of Gaseous Fuels are far below Liquid Hydrocarbon fuels, other than the challenges faced by metals turning brittle due to exposure of excess Hydrogen molecules in these gaseous fuels. These are challenges which cannot be solved over Night.

Climate Change has affected all Living Life on our Planet – We need to try all available options, to unlock the Hidden Potentials of fuel burning to overcome these challenges by finding Cost effective, Workable Solutions in these crucial Times !?? As Electrics will not fix the present situations other than the large investments needed Compared to my simple suggestions of improvements in existing engines – We have 12 more Years left for the survival of IC Engines ,,,, To bring out the hidden Potentials of Combustion to prove my Simple Solutions !

Take a think on what has been conveyed !

To save the future, we must stop living in the past!!

Tailwinds,

Somender Singh